Following the Line: Proportional Control with 2 Sensors

Motivation

Line following with proportional control using one sensor is quite an improvement to on/off control. Yet, it’s not perfect - if the reflectance sensor crosses over the center of the line, it’s game over.

The issue is - the robot has no way of knowing which side of the line it is following at all! If it sees the right edge of the line, it will assume it still is detecting the left edge, and thus keep turning right past the point of no return!

It would be neat if we could actually follow the center of the line, and can recognize both cases in which the robot drifts to the left or the right of the center of the line, and makes a correction. This would largely increase the “controllable” range of what the reflectance sensor sees and can correctly react to. Conveniently, it seems like we haven’t yet made use of the second reflectance sensor on the right…

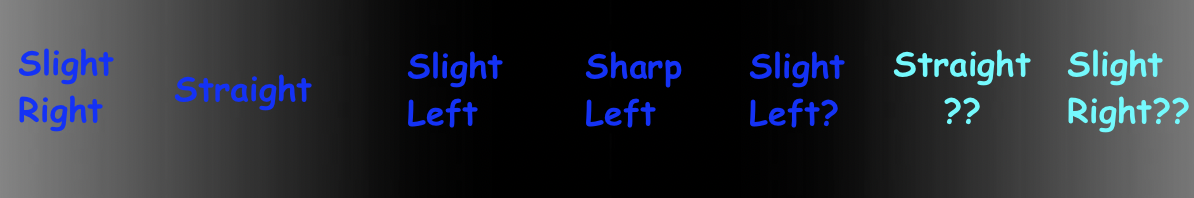

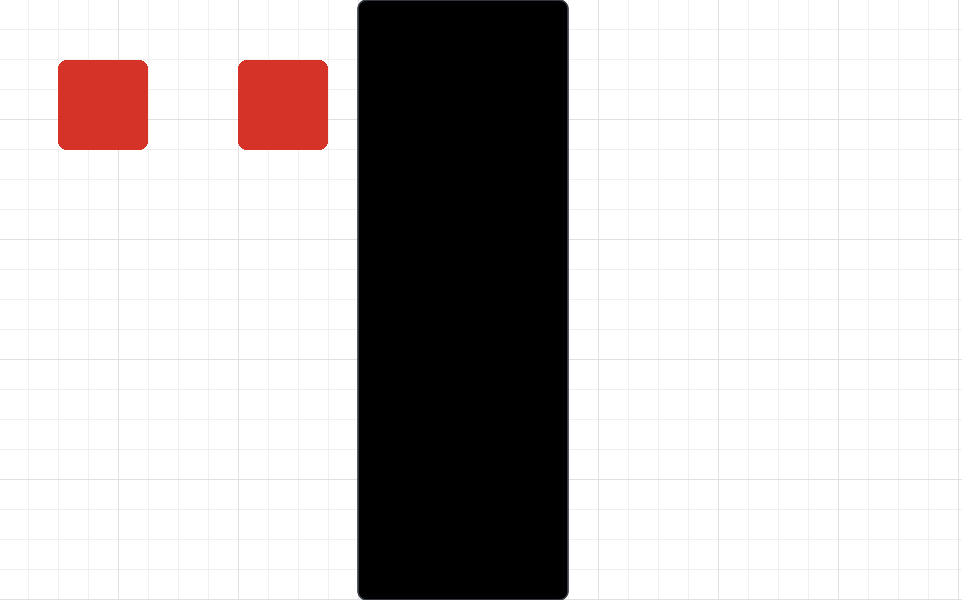

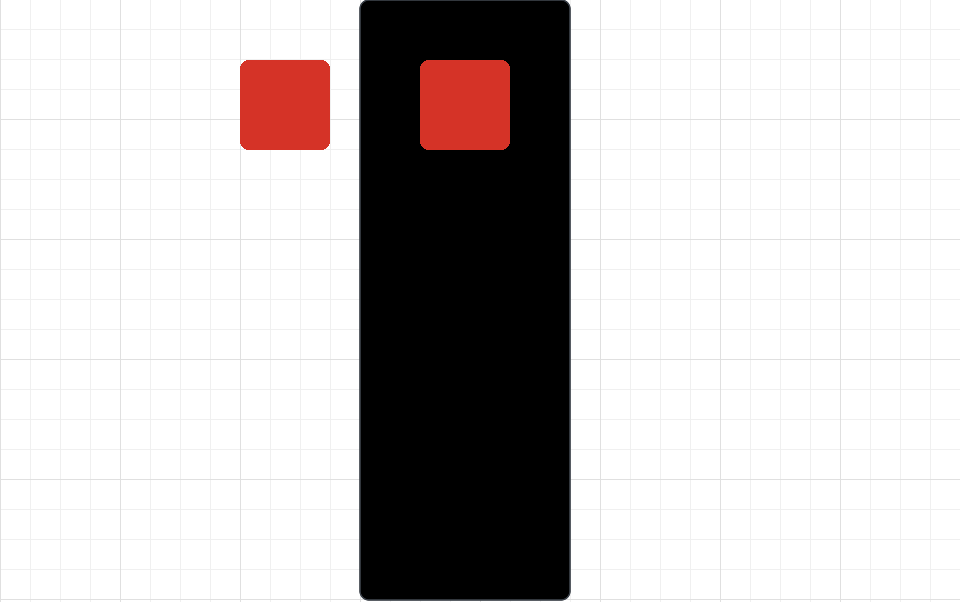

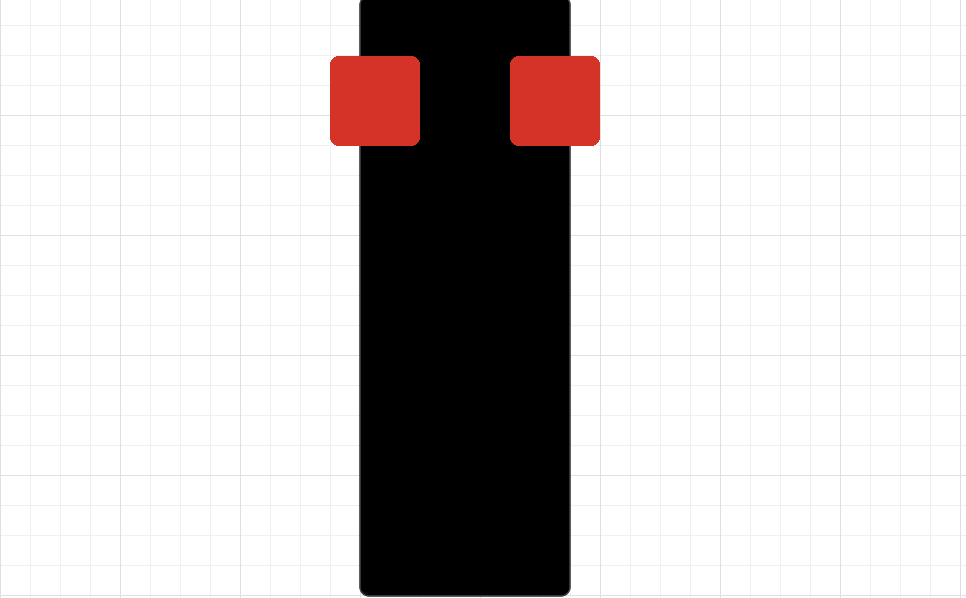

If we recorded the reflectance of both sensors as we moved the robot around the line, there are a few major “categories” of behaviors the robot would perform. For a minute, assume the rectangle is a black line and the two red squares are the location of the reflectance sensors.

Sensors read ~0 and ~0. Robot does not know if it is on either the left or right side of the line.

Sensors read ~0 and ~1. Robot knows it is on the left side and turns right.

Sensors read ~0.5 and ~0.5. Robot knows it is on the center and goes straight.

The other two major categories you can extrapolate for yourself.

So, how can we effectively combine the readings of the left and right reflectance sensors using proportional control to have the robot follow the line? There’s quite an elegant solution that I encourage for you to try to figure out yourselves before the answer is revealed.

Implementation

The big reveal:

error = reflectance.get_left() - reflectance.get_right()

At the beginning this line of code may not make a lot of sense - but let’s dissect it. Remember our previous convention of positive error meaning the robot is too far left and needs to turn right, and vice versa.

In this case, if the robot is following the left edge of the line, then the left sensor detects close to white while the right sensor detects close to black, and so error = (0) - (1) = -1, and the robot turns right. On the other hand, if the robot is following the right edge of the line, error = (1) - (0) = 1, and the robot turns left. When the robot is right at the center, both sensor values are the same and so the error is 0, and as the robot starts drifting towards either direction, the magnitude of the error increases and thus the robot compensates accordingly.

The most interesting case is when the robot is completely off the line - in this case, both sensors read white, leaving an error of (0) - (0) = 0, and so the robot just goes straight. Given that the robot wouldn’t know which direction to compensate if it was completely off the line, this seems like a reasonable result.

And so, our final code is as follows:

KP = 1 # experiment with different values of KP to find what works best

while True:

error = reflectance.get_left() - reflectance.get_right()

drivetrain.set_effort(base_speed - KP*error, base_speed + KP*error)

Here’s what that looks like. Note that KP used in this video was not equal to 1:

INSERT Video

Mini Challenge: Proportional Control with Two Sensors

Combine what you’ve learned with encoders to create a function that follows the line using two sensors for some given distance, and, then stop the motors.

What KP value is best?

Compare one sensor to two sensor line following. What bends in the black line is two sensor line following able to handle that one sensor line following cannot?